A rather cooler but still glorious morning greeted our volunteers who had plenty to look forward to during the day. But priorities were made and the most important job of the day was done early…. Fixing the urn!!

Once this was working again and the crew suitably refreshed (at least until the café was open and a run could be done) we started on our list of jobs. First off was the removal of the starter motor from the Coleman so we could ascertain if it is this that is causing the non-starting. Cue the café run and once breakfast had been demolished, including a large bap that contained more or less everything (it would be quicker to list what it didn’t contain!), we then returned to our tasks. One of the first jobs was to swap out the alternator warning light flasher unit in the power bay. Although being easy to see, the unit is not easy to remove due to the sheer amount of cabling around the fixing points. As a plug runs into the unit, it was deemed more logical to unplug the cable and temporarily connect it to a replacement unit to see if this remedied the intermittent flashing of the alternator warning light. During the first systems demo of the day however, it was noted that the behaviour of the lamp was still the same. As we had another spare unit, this was then swapped and tested again during the second systems demo but with this unit in place the lamp was not illuminating at all. This then led to the original unit being reconnected.

Meanwhile, Derek was continuing with his sterling work prepping and painting the spine of the aircraft and was only beaten when the weather showed signs of changing, ceasing work to allow the areas he had done to dry before the rain came.

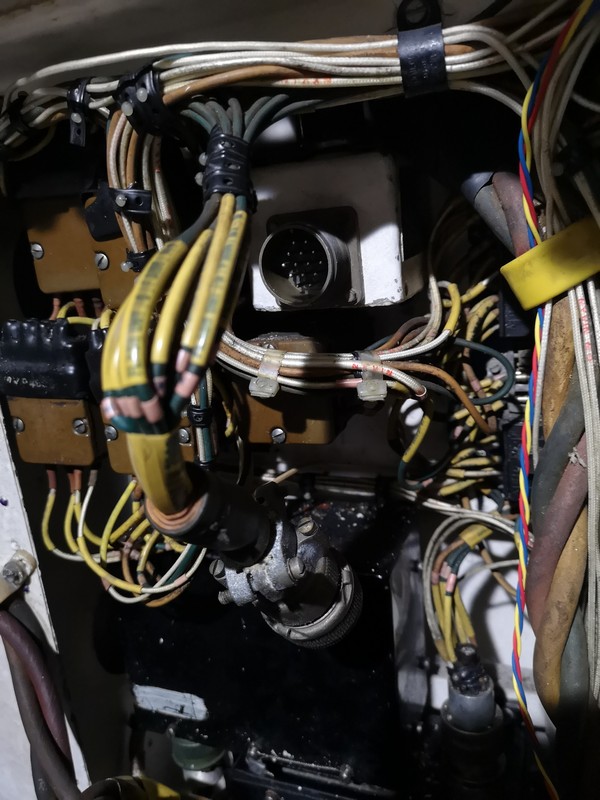

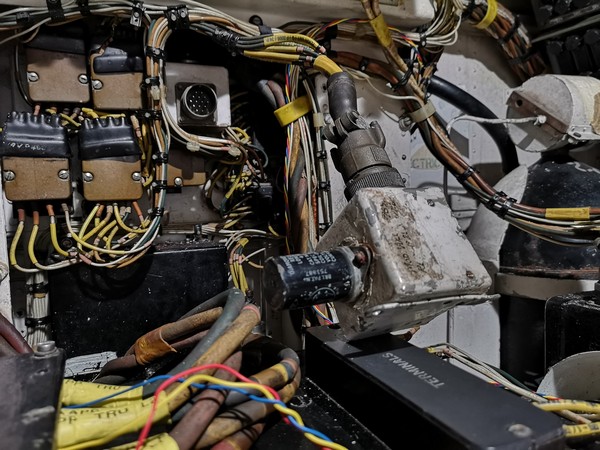

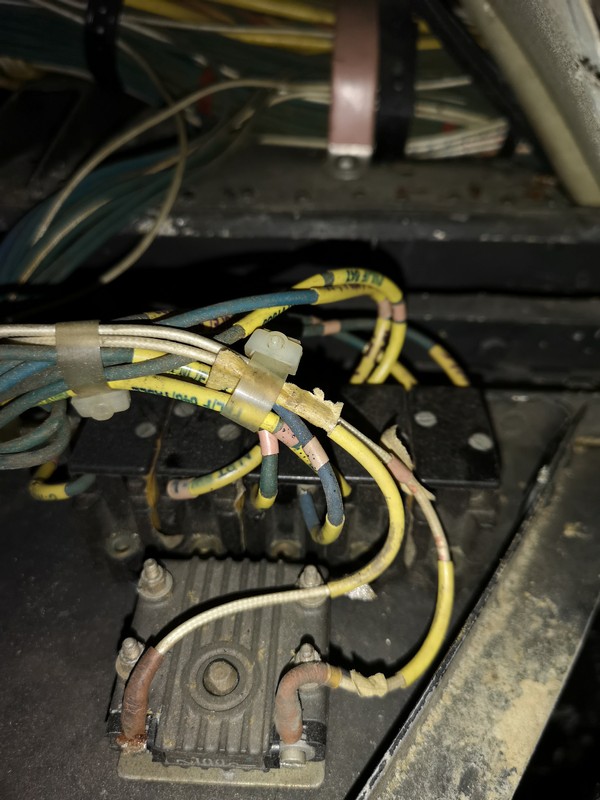

More investigation was done into the recurring issue with the cabin lighting. Although this had been working again, this weekend it decided not to. as the fuse and the light fitting itself had been checked, the next step was to check the wiring and possibly the switch. This involved obtaining access to the rear of the AEO station as the panel containing the cabin light switch is part of a larger panel. the panel was loosened and (gently) lowered after having untangled the tether. This revealed a mass of wiring and control gear but due to upcoming visits, we didn’t have time to investigate further. On first look however, the switch and cabling looked fine. It was decided to then test the cabin lighting again during the afternoon systems demo by activating the abandon aircraft switch. Not only does this illuminate the abandon sign, it also activates the cabin light. The light came on meaning that the issue is elsewhere, possibly in the switching.

Other cabin lighting that received attention was the red fluorescent lighting above the Nav Plotter and AEO stations. Lamps were changed and the AEO and one half of the Nav Plotter lighting was working. Lamp, connections and holders were checked and during the afternoon systems demo, the lighting was observed to be working.

Throughout the day work continued on the riser pump and the bomb trolley with the seals on the pump being worked on. The bomb trolley had a lot of work on it throughout the day, most noticeably the towing arm and creeper gears. Unfortunately one of the rear steering arms didn’t want to budge despite the best efforts of WD40 and numerous tools.

A number of pre booked visits took place throughout the day including our morning group from the Sutton Coldfield Model Makers Society and the afternoon group from the North Cotswold Section Vintage Motorcycle Club. Both groups were treated to a systems demo, talks from our volunteers, cockpit visits and the motorcycles were arranged in front of XM655 for the group photo.

This weekend’s pictures are by Isi, Helen, Len, Matt and James