A bit of a “double header” this week as we not only had our normal Saturday, but some volunteers went on a field trip to visit XL319 in Sunderland… More on that later…

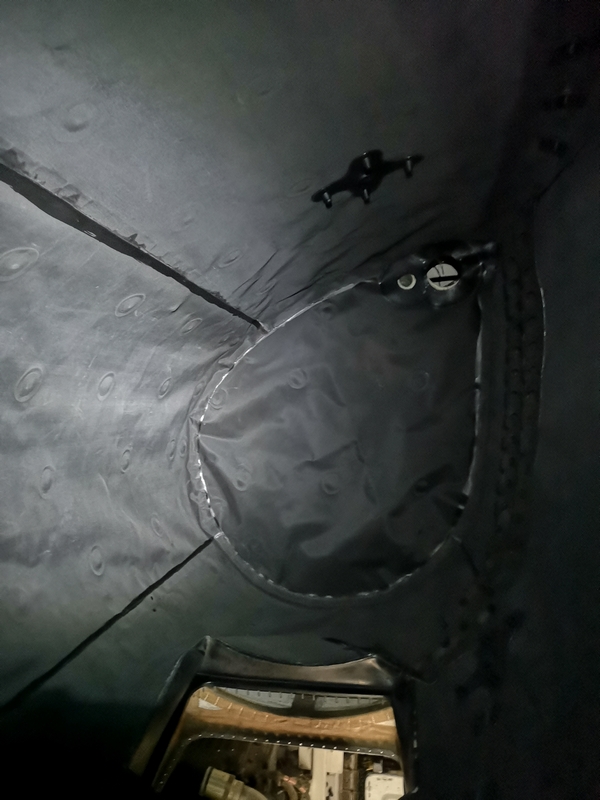

Most of Saturday was spent again on tank work and with both now in the cavities, final checks were made on their fitting. After checking the fixings, it was then time to look at the components which started with the capacitance belts. There are four of these in each tank, two forward and two aft, and these help to measure the fuel levels. The belts are held in place inside the tank by “pockets” and remembering how difficult the ones in the old tank were to remove, we prepared for a struggle! Ideas were using Vaseline or a plastic sleeve allowing free movement of the belts in the pockets. In the end though, after an initial struggle, the belts were fed through the pockets fairly easily. The belts are not smooth and have electrical connections on them which makes the job harder. All four belts were successfully fitted into the port tank with only the rubber retaining studs to sort out.

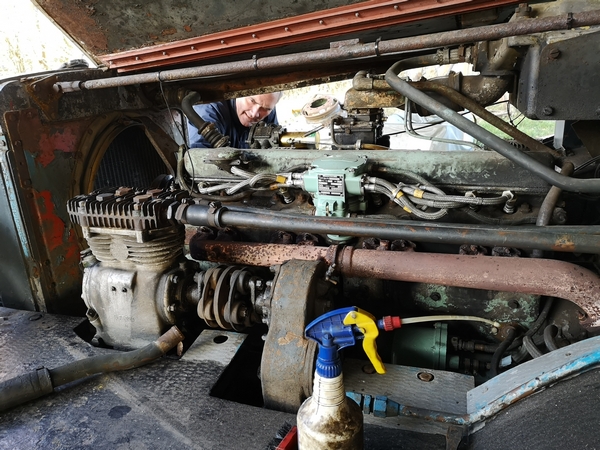

Some work was also carried out on the Sentinel Tug to try and rectify the overheating issues she has been suffering with and preparations were made for the away day. These included familiarising ourselves with where we would be looking on the aircraft, what to look for and loading tools and equipment, to prepare ourselves for the trip to Sunderland and XL319.

Pictures are courtesy of Helen, Isi, James and Steve.